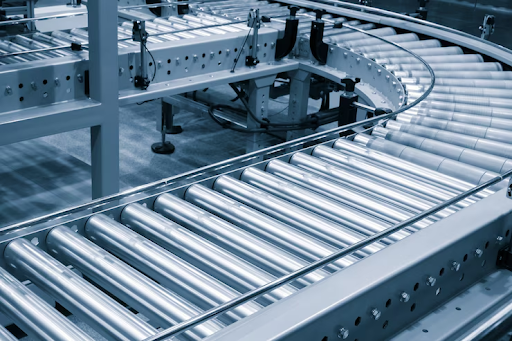

There are a lot of updates available today for warehouses and distribution centers — from robotics to software, all the way to old favorites being renewed. Choosing the right tools to invest in might seem a bit overwhelming given the amount of choices. Each one has its pros and cons. In this article, we’re going to talk about one subsection of machinery you can capitalize on, accumulation conveyors. We’ll discuss what they are, how they work, and the different types available today. Knowing the right type of accumulation conveyor tech to use in your work environment is critical for your success. They will play a large part in how effective your conveyor systems handle and transport your products.

What is an accumulation conveyor?

An accumulation conveyor is a type of conveyor that is used to collect material — to put it simply, they are designed to stop items in their tracks or hold them. They create temporary buffer zones between products moving up or downstream.

They were first developed for a very specific industry, mining. And are still heavily used in mining and mining-related activities. They served a need — as a dumping ground for materials that had been excavated from the earth and needed to be analyzed for valuables.

An accumulation conveyor can be used to transport materials in a controlled fashion, or it can be used to control the flow of materials into a specific location.

This type of conveyor belt can be made from many different materials, such as steel, aluminum, or plastic. They are designed in a way since such materials require less maintenance. This type of conveyor is normally operated by a chain or a small drive belt. The dive mechanic runs smoothly and continuously, and a sensor – typically a photo eye – activates an air bladder that lowers or raises the drive trains so it connects with the rollers. This sensor looks upstream and determines the zone being controlled. If a product, item, or package enters this zone – actuating the sensor – the air bladder deflates and the apparatus drops allowing the item in question to stay put.

Accumulation conveyor design has the following technical features:

- A photo eye sensor is used to scan products and accumulate them

- Solenoids control troll to air mechanisms

- 9 diameter rollers to carry product

- Multiple speeds and release types

The hardware of the accumulation conveyor systems can be easily configured for small or large parcels, as well as bags, and unpackaged materials or items. These types of systems have adapted to the digital age which means they can be linked to various apps or software with a couple of customization — granting you more control and the benefits of automation.

Type of accumulation conveyors

Accumulation is a must for most conveyor systems nowadays. The ability to properly hold – automatically – certain items is critical for a successful supply chain. Cases need to be put on standby before they can merge, sort, or be routed to a specific station within your framework. Without an accumulation conveyor, your whole process would be too chaotic — your overall throughput would be greatly reduced. At their core, their main benefit is that they decouple downstream from the upstream — which ultimately allows both processes to work more efficiently.

Nevertheless, it’s critical to understand that not all accumulation conveyors are the same. There are two types available in the market right now: minimum accumulation pressure conveyors and zero pressure accumulation conveyors.

Let’s take a look at each — their characteristics, a bit about their anatomy and technicalities, and where each works better.

Minimum pressure accumulation conveyor

A minimum pressure accumulation roller conveyor is a device that helps move material -such as coal, ore, grain, etc – from one point to another. It works by using the weight of the material to push it down onto a series of plates with holes in them.

The plates are arranged so that they form a series of steps. The first plate has the smallest hole and the last plate has the largest hole. The plates are also arranged so that each successive plate is higher than the one before it. As the material falls down through these holes, some of it will fall through onto the next plate below and some will fall off at either side. The material which falls through onto each successive plate will be smaller and smaller until eventually there is only fine dust left on top of this last plate with a large hole.

Zero pressure accumulation conveyor

A zero pressure accumulation conveyor is a conveyor system that has a small opening for the material to enter. This opening has a pressure plate that will not allow any more material to enter the system until it is needed. The benefit of this type of conveyor is that it does not require any form of power and can be operated by gravity.

A zero pressure accumulation roller conveyor does not generate any pressure on the product and is used for sensitive items. A minimum pressure accumulation conveyor, on the other hand, generates a small amount of distress; they are generally employed for much more robust items.

Another main difference is that accumulated items on a minimum pressure conveyor will be in contact with each other; while items on a zero pressure conveyor will not. This might give the latter at first sight a bit of an advantage – it might seem superior – but the truth is that minimum pressure conveyors are far more ideal for items that share the same weight and dimensions.

Benefits of accumulation conveyors

These types of conveyors are often used in the manufacturing process to move materials from one point to another. Accumulation conveyors can be seen in many different industries such as pharmaceuticals, food production, and recycling.

The benefits of accumulation roller conveyors are that they can help with storage and transportation. They allow for the easy movement of products without having to use the same amount of labor as other methods would require. The other benefit is that this machinery does not require any additional floor space because it is on a raised level or the ground. This makes it very efficient in some cases and allows for more room for other things like machinery or equipment.

Skip to main content

Skip to main content