Have you had disruptions in delivery schedules owing to unexpected delays in getting inventory from the warehouse? How about orders that you have lost because you do not have the product that you have promised to deliver?

What is warehouse optimization? Why is it important?

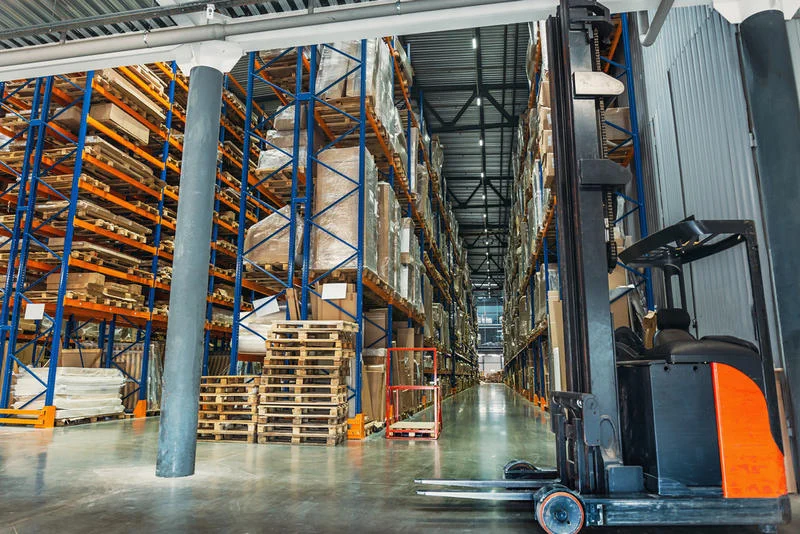

The warehouse is the backbone of any business, big or small. With efficient warehouse optimization, you have the optimal method to execute orders right until they reach customers. Warehouse optimization encompasses myriad processes including order docking, inventory, and shipping. This also helps streamline your production flow and transportation processes through all deadlines.

Optimization is not only beneficial for warehouse process streamlining and productivity but also for improved business performance overall.

What 5 steps can be important in warehouse optimization?

Step 1 – Use warehouse software solutions

An effective warehouse management software (WMS) is a tool that enables control and management of warehouse operations that occur daily. Be it intake of inventory or stacking in the right places or picking and transporting orders, the software helps keep tabs on it all from one unified platform.

A well-designed warehouse management software lets you gain maximum control of the warehouse processes so the disruptions arising from here are minimized. Plus, it lets you do this all with minimal human resources meaning that your cost remains within reason.

Check out our unique, flexible, reliable WMS package, SwiftCurrent.

Step 2 – Automated material handling system

Automating the material handling helps reduce human errors in storage of material, its distribution and order fulfillment. The software significantly enhances your ability to keep track of products and materials. It also improves efficiency within the warehouse because workers can quickly locate what they need. Reliable updates about delivery schedules and product availability can be obtained thanks to automated material handling systems.

Another huge advantage of automated material handling is that you eliminate the risk of oversight of depleted inventories. The system automatically throws up a warning when inventories approach depletion so that you can restock well in time and avoid delays in meeting demand.

Step 3 – Automate processes

The biggest advantage you derive from automation is to free up valuable human resources for other crucial tasks. Automation may take different forms depending on the size of your business, the magnitude of orders you deal with on a daily basis, and the complexity of the system you have in place. For example, the smallest of warehouses can benefit from an automated warehouse system to keep track of what comes in and goes out.

Step 4 – Maintain warehouse equipment list

Create a warehouse equipment list that tells you which equipment you need given the specific conditions and requirements in your warehouse. Once you have all the equipment in place, this list tells your warehouse staff which equipment they have at their disposal to carry out various tasks. Note that using the right equipment for the right task minimizes time is taken and risk to the individual as well as risk of damage to the product.

Step 5 – Standardize processes

Setting standards for processes ensures seamless training of new staff while also promoting uniformity, consistency, and predictability in the warehouse processes. With an automated warehouse system, you can standardize processes easily and also have in place checks to ensure everyone is following the guidelines. Standardization also helps maintain high product and service quality across the board and improves your ability to follow through on commitments made to customers.

What are the main reasons to optimize a warehouse?

Warehouse optimization not only makes the work easier and quicker on a daily basis but also offers several key long-term advantages:

- Efficient customer service and improved customer retention

- Ability to meet demand with least turnaround times

- Disruption-free daily operations

- Smooth production flow

- Planned delivery schedules

- Organized and thus safer warehouse workspace

- Better forecasting and thus efficient space utilization

Talk to us today to know more about efficient warehouse optimizing solutions and how you can make strides in the right direction for your company.

Skip to main content

Skip to main content